For Small Engine Tanks, Portable Gas Cans, and High Performance Packaging

“Co-Extrusion is the proven answer that can grow and adapt as permeation regulations tighten and flexible fuels evolve.”

Co-Extrusion Benefits:

- 82% of the world's automotive fuel tanks are presently in Co-Extruded plastic.

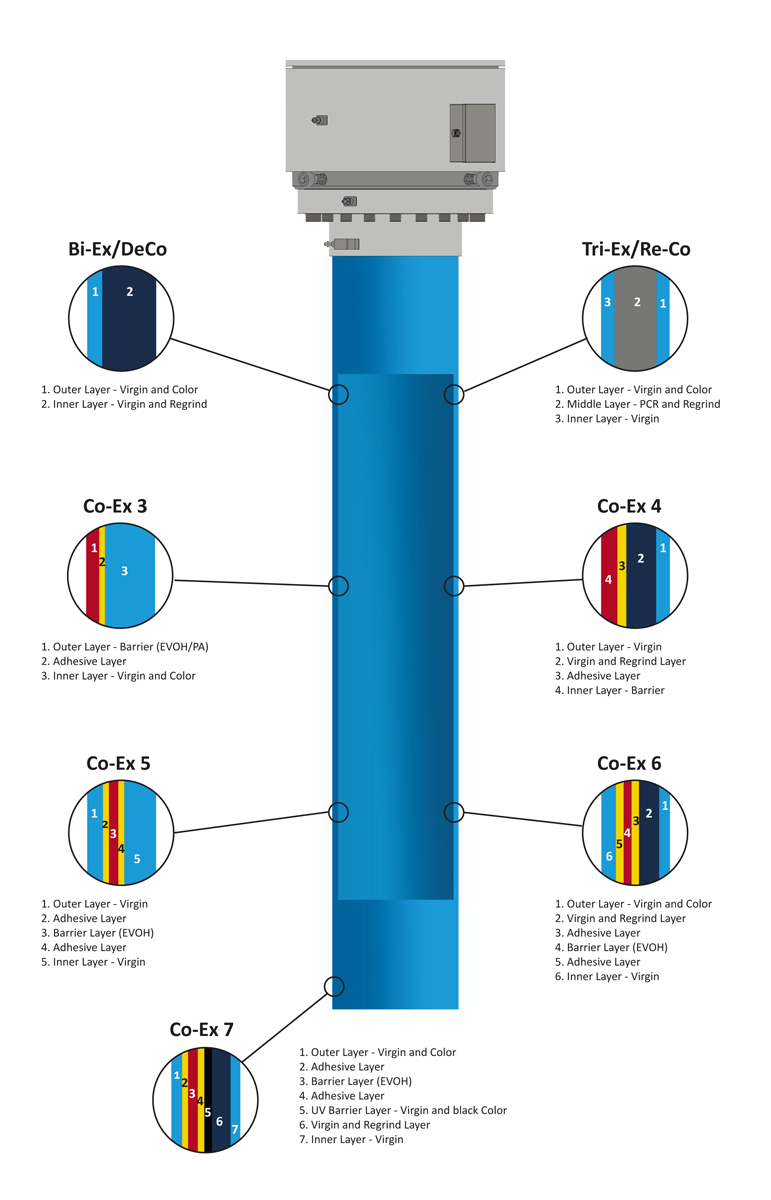

- Manufacturing economics are favorable with Co-Extrusion as the barrier layer typically only represents 3% of the total wall structure.

- Co-Extrusion meets the current fuel emission regulations as established by CARB and the EPA.

- Co-Extrusion structures and materials can be tailored to address flexible fuels.

- 2-7 layer systems

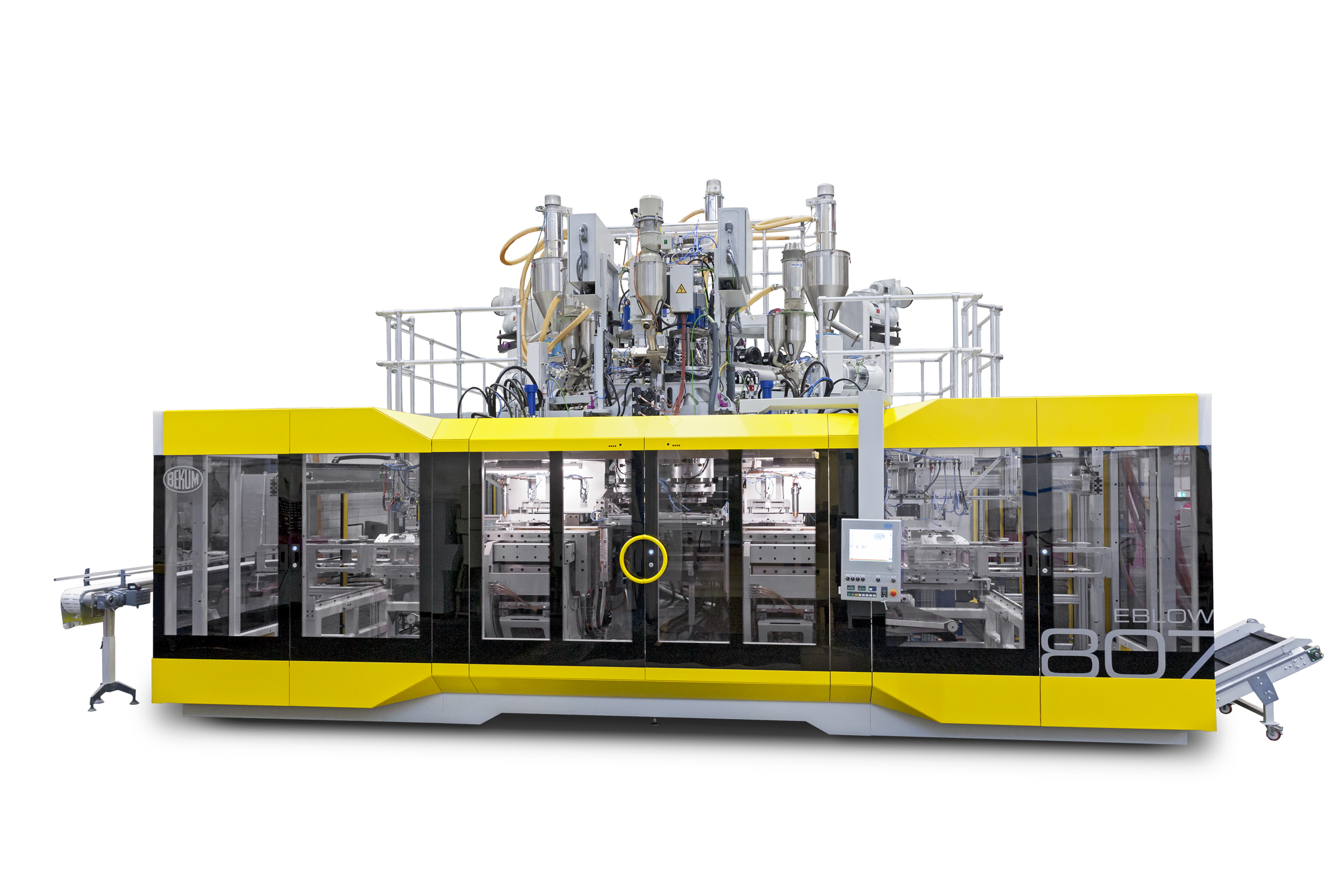

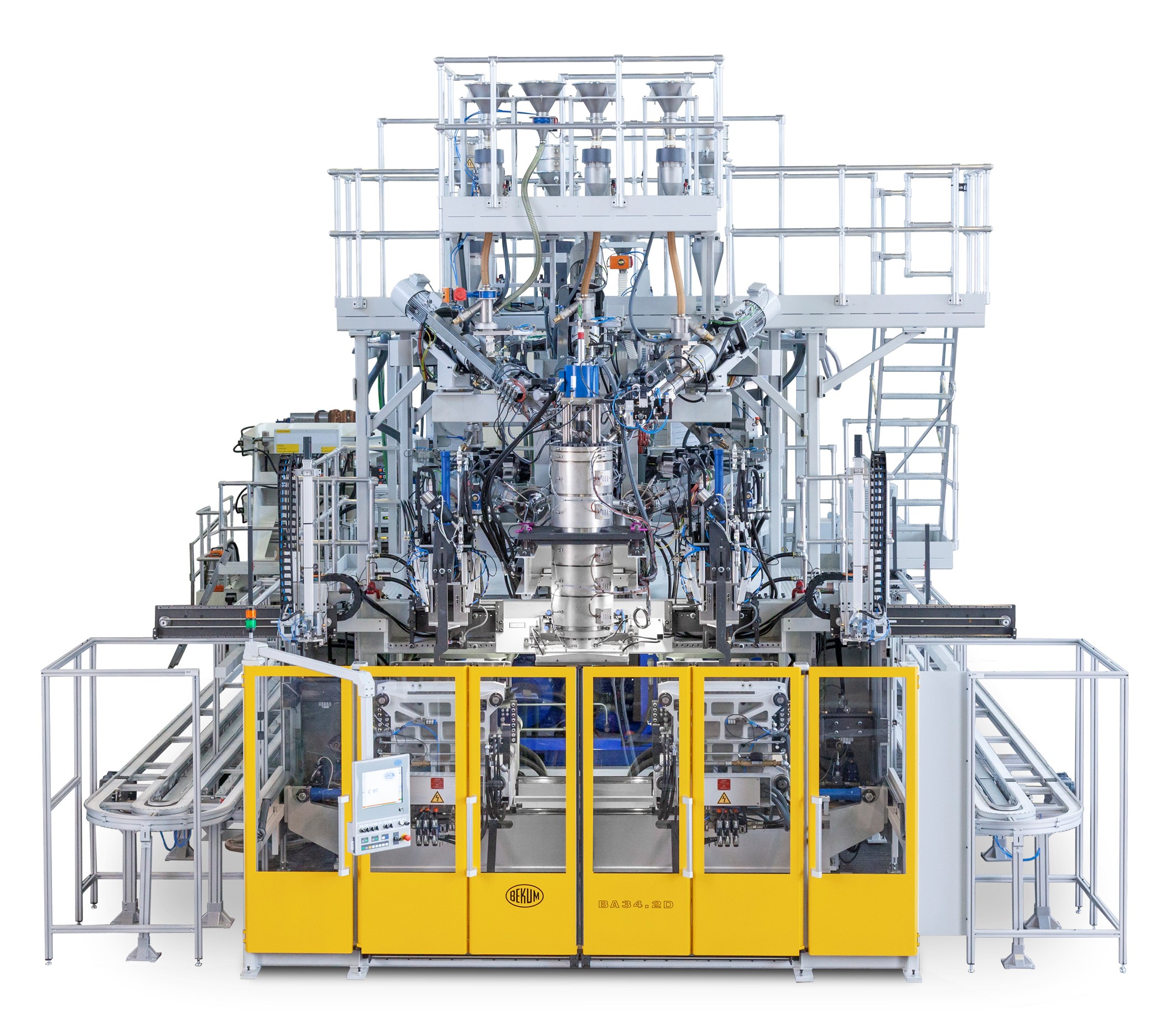

- Up to 6-parison Co-Ex heads, 6-layer

- Up to 12-parison Tri-Ex heads, 3-layer

- Barrier layer thickness accuracy of +/- 10 microns

- A full range of Co-Extrusion heads with die sizes from 30-600 mm.

- Single and double station machines with clamp sizes for 1 to 220 liter articles.

- Package enhancements include:

- Extended shelf life

- Oxygen barrier

- UV and light protection

- Chemical barrier

- Flavor & odor barriers

- Recycling

- 30+ Years of Co-Extrusion experience.

- Bekum Worldwide service and support

Profit from our Experience!

For after-hours Service assistance, call or text (517) 927-2958