Profit from our experience

|

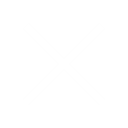

Models

|

|

Models

|

|

Models

|

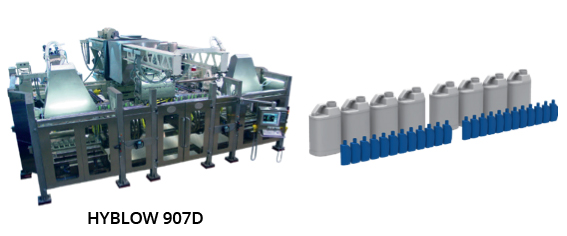

Tandem Blow

- Up to 150 million bottles/yr. output

- Bottles blown base-to base or neck-to-neck

- Each parison yields 4 cavities of production (double sided)

- Up to 40 cavities

- Ideally suited for high output co-extrusion

|

Models

|