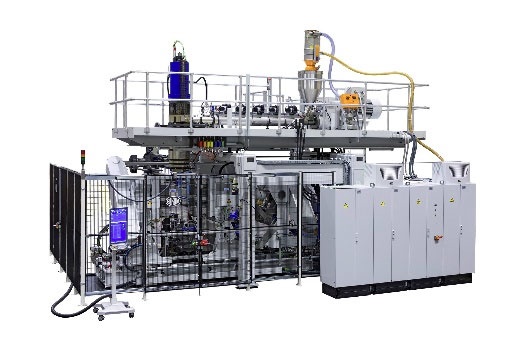

New machine concept for canisters, IBCs, drums, water tanks and various technical parts.

The newly designed XBLOW series includes machine sizes 50, 100, 200 and 300, which are available as single‐station machines. The heart of this series is the central clamping unit with two diagonal spars and a two‐stage hybrid‐electric clamping drive for clamping forces of 500 ‐ 3,000 KN. By using servo hydraulics, the energy requirement could be significantly reduced. The use of blow moulds of different thicknesses is designed in mind. Using the new Bekum Control 8.0 machine control system on the HMI, the operator can conveniently and easily adjust very large variable mold thicknesses that are not possible with other electric clamping drives of large blow molding systems. The system does not have to be mechanically adjusted. While the clamping unit is arranged centrally under the stage with battery heads, continuous heads require a slightly offset position. Modern and quiet speed‐controlled hydraulic power units reduce energy consumption and reduce the noise level to 71 dB(A).

| Technical Specs | |||||

| Single and double* station blow molding machines | EBLOW 38S EBLOW 38D* | XBLOW 50 | XBLOW 100 | XBLOW 200 | XBLOW 300 |

| Clamping Forces (kN) | 400 | 500 | 1000 | 2000 | 3000 |

| Clamping forces (US t) | 44.8 | 56.2 | 112.4 | 224.8 | 337.2 |

| Mold width, max. (mm) | 780 | 800 | 1200 | 1500 | 2200 |

| Mold Length, max. (mm) | 750 | 800 | 1500 | 1800 | 2200 |

| Mold Thickness | 2 x 200 2 x 250 |

2 x 250 2 x 350 |

2 x 300 2 x 470 |

2 x 400 2 x 650 |

2 x 500 2 x 700 |

| Mold opening path (mm) | 400 | 700 | 850 | 1200 | 1200 |

| Mold stroke (mm) | 720 / 780 750 / 800 | ||||

| Article production capability per mold, max. (l) | 30 | 60 | 250 | 1000 | >1000 |

Machine standard is bold

Profit from our Experience!

For after-hours Service assistance, call or text (517) 927-2958

XBLOW 50

XBLOW 50 XBLOW 100

XBLOW 100